What Happens When Ac Contactor Goes Bad: Common Problems And Effective Solutions

When an AC contactor goes bad, it can cause the entire cooling system to fail. This can result in a lack of cool air and discomfort in hot weather. Common problems include faulty connections preventing power flow and worn-out contactors needing replacement. Understanding the signs and knowing how to troubleshoot can help prevent expensive repairs and safety hazards.

In the sweltering heat of summer, homeowners rely on their trusty air conditioning systems to provide cool relief. But what happens when the heart of the system, the AC contactor, goes bad? The consequences can be more than just an inconvenience; they can leave you sweating profusely while your once-cool oasis transforms into a sauna.

Unbeknownst to many, the AC contactor plays a vital role in the functioning of your air conditioner. When it fails, so does the entire cooling system.

But fear not, for there are effective solutions to these common problems. Whether it’s a faulty connection preventing power flow or a worn-out contactor that needs replacing, understanding the signs and knowing how to troubleshoot can save you from expensive repairs or even potential safety hazards. In this article, we dive deep into the world of AC contactors, uncovering the most common problems and equipping you with the knowledge to tackle them head-on.

Get ready to reclaim the cool comfort you deserve.

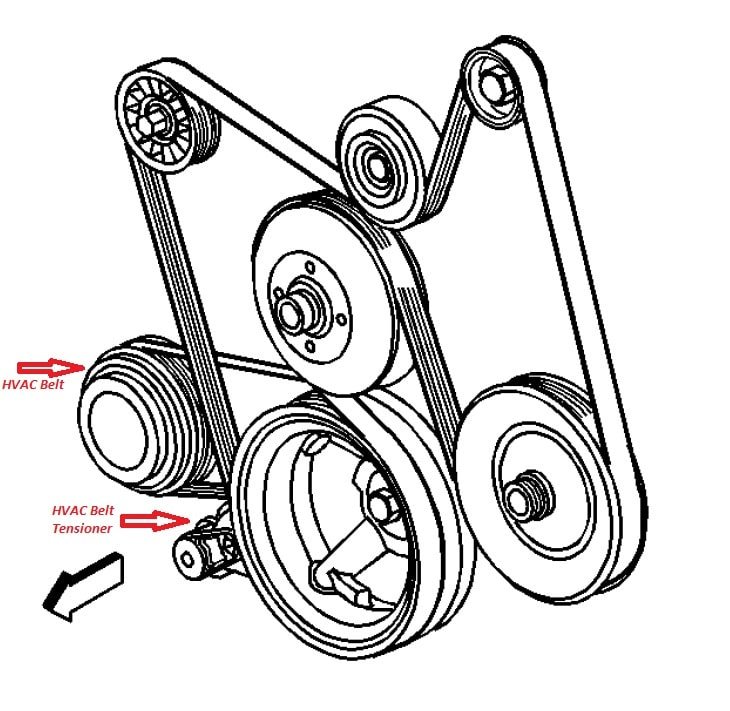

I. Understanding the AC Contactor A. Definition and Function of an AC ContactorAn AC contactor is an essential component of an air conditioning system that plays a crucial role in controlling the flow of electricity to the unit. It acts as a switch, allowing the power supply to connect or disconnect from the compressor and the condenser fan motor. When the thermostat signals the need for heating or cooling, the AC contactor is responsible for engaging the necessary electrical circuits to initiate the system’s operation.

B. Components of an AC ContactorA typical AC contactor consists of several key components:

- Coil: The coil is an electromagnetic component that generates a magnetic field when an electrical current flows through it. This magnetic field is responsible for pulling the contacts together when the contactor receives a signal from the thermostat.

- Contacts: The contacts are metal plates that make or break the electrical connection between the power supply and the air conditioning unit. They are designed to handle high voltages and currents, ensuring a reliable flow of electricity.

- Terminals: The terminals are points of connection where the electrical wires from the power supply, the thermostat, and the air conditioner are attached. They allow for the transfer of electrical energy to and from the contactor.

- Arc Shield: The arc shield is a protective cover that surrounds the contacts to prevent the formation of an electric arc during contact separation. It helps maintain the integrity of the contactor while minimizing the risk of electrical damage or fire hazards.

- Mechanical Latch: The mechanical latch holds the contacts in the closed position once the coil has pulled them together. This ensures a continuous flow of electricity to the air conditioning system until the thermostat signals for the system to shut off.

A well-functioning AC contactor is crucial for the proper operation of an air conditioning system. Without it, the electrical circuit that powers the compressor and the condenser fan motor would remain open, preventing the cooling or heating process from occurring. By engaging the contacts and closing the circuit, the contactor allows the necessary electrical current to flow to the vital components of the AC unit, enabling it to function efficiently and effectively.

When the AC contactor is in good condition, it ensures that electricity is distributed properly, minimizing the risk of electrical issues, energy waste, and potential damage to other components of the air conditioning system. It also contributes to the overall safety and reliability of the system, allowing homeowners to enjoy a comfortable indoor environment without worrying about malfunctions or failures.

II. Signs and Symptoms of a Bad AC Contactor A. Frequent Tripping of Circuit BreakersOne of the most common signs of a bad AC contactor is frequent tripping of circuit breakers. When the contactor is faulty, it may fail to engage or disengage the electrical circuit properly, causing an overload in the system. This overload can trigger the circuit breakers to trip, cutting off the power supply to the air conditioning unit.

If you notice that your circuit breakers are constantly tripping when your air conditioner is running, it could be a clear indication of a malfunctioning contactor that needs attention.

B. Inconsistent Cooling or HeatingA bad AC contactor can also result in inconsistent cooling or heating performance. When the contactor fails to close the electrical circuit properly, it may prevent the compressor or the condenser fan motor from receiving the necessary power supply. This can lead to inadequate cooling or heating, resulting in uneven temperatures and discomfort in your home.

If you find that certain areas of your home are significantly warmer or colder than others, even when the air conditioner is running, it might be a sign that the contactor is not functioning correctly.

C. Unusual NoisesUnusual noises coming from the air conditioner can also indicate a bad AC contactor. When the contacts are worn out or damaged, they may produce a buzzing or humming sound as electricity passes through them. These abnormal sounds can be a result of arcing, poor connections, or loose components within the contactor.

If you hear any strange noises emanating from your air conditioning unit, it’s crucial to investigate the source and have a professional inspect the contactor for potential issues.

D. Burn Marks or Damage on the ContactorVisually inspecting the AC contactor can reveal valuable information about its condition. If you notice burn marks, discoloration, or any signs of damage on the contactor, it’s a clear indication of a problem. These signs typically suggest that the contactor has been subjected to excessive heat or arcing, leading to degradation and potential failure.

A damaged contactor should be addressed promptly to prevent further damage and ensure the safe and reliable operation of your air conditioning system.

E. Difficulty in Starting or Stopping the AC UnitA faulty contactor can manifest in difficulty starting or stopping the air conditioning unit. When you attempt to turn on the AC, you may notice a delay or a complete failure in the system’s response. Similarly, when you try to turn off the AC, it may continue to run despite the command to shut down.

These issues can be attributed to a contactor that is unable to establish or break the electrical connection effectively. If you experience any difficulties in controlling your air conditioner’s operation, it’s advisable to have the contactor inspected and, if necessary, replaced.

F. Frequent Electrical Issues in the HomeA bad AC contactor can cause electrical issues beyond the air conditioning system. As the contactor starts to fail, it may result in voltage fluctuations or power surges that affect other electrical appliances in your home. Lights flickering, outlets malfunctioning, or appliances experiencing erratic behavior could all be symptomatic of a faulty contactor.

If you notice an increase in electrical issues throughout your home, it’s essential to have the contactor examined to determine if it is the root cause.

IV. Causes of AC Contactor Failure A. Normal Wear and TearLike any mechanical component, AC contactors are subject to normal wear and tear over time. The repeated opening and closing of the contacts, exposure to electrical currents, and environmental factors can gradually degrade the contactor’s performance and reliability.

As the contactor ages, the electrical contacts may become pitted or worn, hindering their ability to make a solid connection. The coil may also weaken or develop insulation issues, affecting the contactor’s ability to generate a magnetic field and engage the contacts effectively.

B. Electrical OverloadElectrical overload is another common cause of AC contactor failure. When the air conditioning system operates under excessive electrical loads, the contactor may be subjected to high levels of current or voltage. This can lead to overheating, arcing, or even melting of the contacts, compromising their integrity and functionality.

Electrical overloads can occur due to issues such as undersized wiring, faulty circuit breakers, or malfunctioning electrical components within the air conditioning system. It’s crucial to address any electrical problems promptly to prevent contactor failure and potential safety hazards.

C. Dust and Debris AccumulationDust and debris can accumulate on the surface of the AC contactor over time, particularly if it is located in an exposed or poorly ventilated area. This buildup can inhibit the proper operation of the contactor, impairing its ability to make and break electrical connections efficiently.

The presence of dust and debris can also exacerbate wear on the contacts, leading to premature failure. Regular cleaning and maintenance can help prevent these issues and extend the lifespan of the contactor.

D. Corrosion or RustMoisture and exposure to the elements can cause corrosion or rust to develop on the contactor’s components. Corrosion can interfere with the contactor’s electrical conductivity, impeding the flow of electricity and compromising its performance.

Rust can cause mechanical components, such as the contacts or the mechanical latch, to seize or become less responsive. This can lead to difficulties in engaging or disengaging the electrical circuit, resulting in contactor failure.

E. Poor Installation or MaintenanceIncorrect installation or inadequate maintenance practices can contribute to premature contactor failure. Improper wiring, loose connections, or inadequate protection against environmental factors can all impact the contactor’s performance and longevity.

Regular maintenance, including cleaning, inspection, and tightening of connections, is vital in ensuring the contactor functions optimally. It’s essential to hire qualified professionals to handle the installation and maintenance of your air conditioning system to minimize the risk of contactor failure.

F. Power Surges or Voltage FluctuationsPower surges, voltage fluctuations, or electrical spikes can cause significant stress on the AC contactor, potentially leading to its failure. These sudden increases or decreases in voltage can generate excessive heat or arcing, damaging the contactor’s components.

Power surges can occur due to lightning strikes, utility company issues, or electrical faults within the home. Installing surge protectors and voltage regulators can help mitigate the risks associated with power surges and fluctuations, safeguarding the contactor and other sensitive electrical equipment.

V. Potential Risks and Consequences of a Bad AC Contactor A. Reduced Energy EfficiencyA bad AC contactor can significantly impact the energy efficiency of your air conditioning system. When the contactor fails to engage or disengage the electrical circuits properly, it can cause the compressor or the condenser fan motor to run longer than necessary. This prolonged operation leads to increased energy consumption, resulting in higher electricity bills.

By promptly addressing contactor issues and ensuring its proper functioning, you can maintain optimal energy efficiency and keep your cooling or heating costs in check.

B. Increased Energy ConsumptionInefficient functioning of the AC contactor not only affects energy efficiency but also increases overall energy consumption. When the contactor is faulty, it may result in the unnecessary operation of the air conditioning system, running the compressor and the condenser fan motor more frequently and for longer durations.

This increased energy consumption not only puts a strain on your wallet but also contributes to higher carbon emissions and negative environmental impacts. Regular maintenance and prompt contactor repairs can help reduce energy waste and promote sustainability.

C. Potential Damage to Other ComponentsA malfunctioning AC contactor can have a domino effect on other components of the air conditioning system. When the contactor fails, it can cause voltage fluctuations or electrical issues that affect the operation and performance of other electrical components.

Components such as the compressor, condenser fan motor, capacitor, or even the control board can be subjected to stress and potential damage as a result of contactor failure. Addressing contactor problems promptly can help prevent further damage to these critical components.

D. Safety Hazards and Fire RisksAC contactor failure can pose safety hazards and fire risks. When the contactor’s electrical connections are compromised, they can generate heat, arcing, or sparks that can lead to electrical fires.

Additionally, contactor failure may result in unstable electrical currents or voltage fluctuations, increasing the risk of electrical accidents, shock, or electrocution. Regular maintenance, inspection, and replacement of faulty contactors are crucial in maintaining a safe and secure air conditioning system.

VI. Troubleshooting and Diagnosing a Bad AC Contactor A. Visual Inspection of the ContactorPerforming a visual inspection of the AC contactor can help identify potential issues. Start by turning off the power supply to the air conditioning system to ensure safety.

Inspect the contactor for any signs of burn marks, discoloration, or damage on the contacts or other components. Check for loose or frayed wires, loose connections, or any debris that may be obstructing the contactor’s operation.

If you notice any visible problems, it is advisable to consult a professional HVAC technician for a more thorough evaluation and repair.

B. Testing the Contactor for Continuity and ResistanceUsing a multimeter, you can test the contactor for continuity and resistance to determine its functionality. Start by disconnecting the power supply to the air conditioning system to ensure safety.

Set the multimeter to the resistance or continuity mode and touch the contactor’s terminals with the multimeter probes. If you get a reading close to zero or hear a continuous beep, it indicates that the contactor is closed and functioning properly.

If there is no reading or a significantly high resistance reading, it suggests that the contactor is open and needs to be replaced.

C. Checking for Loose or Damaged WiringLoose or damaged wiring can affect the performance of the AC contactor. Inspect the wiring connections leading to and from the contactor, ensuring that they are secure and free from any signs of damage.

Tighten any loose connections and replace any frayed or damaged wires. Be sure to follow proper safety procedures and turn off the power supply before working on any electrical components of the air conditioning system.

D. Observing the Contactor’s Response to Voltage InputObserving the contactor’s response to voltage input can provide valuable insights into its condition. Start by turning on the power supply to the air conditioning system and activating the thermostat to call for cooling or heating.

Observe the contactor to see if the coil is receiving the appropriate voltage and if it engages or disengages the contacts as expected. A properly functioning contactor should exhibit a smooth response, with the contacts closing and locking into place when the coil is energized.

If the contactor fails to engage or disengage or if there are any irregularities in its response, it indicates a potential problem that should be addressed by a professional HVAC technician.

VII. Steps to Replace a Bad AC Contactor A. Safety PrecautionsBefore replacing a bad AC contactor, it’s crucial to prioritize safety. Start by turning off the power supply to the air conditioning system at the circuit breaker. This step ensures that no electrical current is flowing to the unit and minimizes the risk of electrical accidents.

Wearing appropriate personal protective equipment, such as gloves and safety goggles, is also recommended to protect against any potential hazards.

B. Gathering the Necessary Tools and EquipmentTo replace a bad AC contactor, gather the necessary tools and equipment:

- Flathead screwdriver

- Insulated multimeter

- Wire cutters/strippers

- Electrical tape

- New AC contactor

Having these tools readily available will ensure a smooth and efficient replacement process.

C. Shutting Off the Power SupplyBefore replacing the contactor, shut off the power supply to the air conditioning system at the circuit breaker. This step prevents any electrical accidents and ensures a safe working environment.

D. Removing the Old ContactorStart by removing the cover of the air conditioning unit to expose the contactor. Take note of the existing wiring connections and their placements.

Using a flathead screwdriver, carefully remove the mounting screws that secure the contactor in place. Once the screws are removed, gently pull the contactor away from the unit, exposing the wiring connections on the sides.

E. Installing and Wiring the New ContactorCompare the new contactor with the old one to ensure compatibility. Ensure that the new contactor has the same specifications and terminal configurations as the old one.

With the new contactor in hand, begin by wiring it according to the markings on the terminals. Use wire cutters or strippers to strip the insulation from the wire ends, then attach each wire securely to its corresponding terminal.

Take note of the wiring connections from the previous contactor and replicate the same connections on the new one. Ensure that all connections are tight and secure to prevent any electrical issues.

F. Testing and Verifying Proper FunctionalityOnce the new contactor is wired, double-check all the connections to ensure their accuracy and tightness. Next, turn on the power supply at the circuit breaker.

Using an insulated multimeter, test the contactor for continuity and resistance as described earlier. Verify that the contactor engages and disengages the contacts as expected when the thermostat signals the need for cooling or heating.

If everything checks out and the contactor functions correctly, replace the cover of the air conditioning unit, and your new contactor is ready to keep your system running smoothly.

VIII. Preventive Maintenance for AC Contactors A. Regular Cleaning and InspectionRegular cleaning and inspection of the AC contactor can help prevent issues and ensure its optimal performance. Start by turning off the power supply to the air conditioning system.

Using a soft brush or a compressed air canister, remove any dirt, dust, or debris from the surface of the contactor. Pay particular attention to the contacts, ensuring they are free from any buildup that may hinder their proper operation.

Inspect the contactor for signs of damage, burn marks, loose connections, or any other issues. Tighten any loose connections and address any visible problems promptly.

B. Keeping the Contactor Area Clear of DebrisMaintaining a clear area around the contactor is essential to prevent the accumulation of dirt, leaves, or other debris that can impede its functionality. Regularly inspect the contactor area and remove any obstructions to ensure unobstructed operation.

Trim any overgrown vegetation or branches that may come into contact with the contactor, causing potential damage or interference with its operation.

C. Proper Lubrication of Moving PartsIf your contactor has moving parts, such as the mechanical latch, proper lubrication can help ensure smooth operation and reduce wear. Consult the manufacturer’s guidelines or a professional technician to determine the appropriate lubricant and method of application.

Remember to turn off the power supply before performing any maintenance tasks and avoid over-lubrication, as it can attract dust and debris, further compromising the contactor’s performance.

D. Addressing and Fixing Electrical Issues PromptlyElectrical issues within the air conditioning system should be promptly addressed to prevent damage to the contactor. Any signs of voltage fluctuations, power surges, or abnormal electrical behavior should be investigated by a qualified HVAC technician.

Regularly monitor your electrical system and promptly address any electrical problems to safeguard the contactor and other sensitive electrical components.

E. Scheduling Professional MaintenanceWhile regular DIY maintenance is essential, scheduling professional maintenance for your air conditioning system is highly recommended. A qualified HVAC technician can perform a comprehensive inspection, cleaning, and tune-up, ensuring that all components, including the contactor, are in optimal condition.

Professional maintenance visits can help identify potential issues before they escalate, prolong the lifespan of your air conditioning system, improve energy efficiency, and enhance overall performance and reliability.

IX. ConclusionA well-functioning AC contactor is vital for the proper operation and efficiency of your air conditioning system. Understanding the signs of a bad contactor and being able to troubleshoot and diagnose issues can save you from costly repairs, energy waste, and potential safety hazards.

Regular maintenance, prompt replacement of faulty contactors, and professional HVAC services are key to keeping your contactor and entire air conditioning system in optimal condition.

Remember, when it comes to AC contactors, prevention and proactive maintenance are the keys to a cool and comfortable home.

- ♥【What You Get】The package comes with 1P 40A 24V hvac contactor.Pole:1;Full load rated current(FLA):40A;Resistive load rated current(RES):50A;Coil:24VAC,50/60Hz;Compatible with devices up to 600 VAC.

- ♥【Superior Quality】Stable and durable.Preferred flame retardant housing; high quality silver alloy contacts, not easy to oxidize; full turn coil purple copper coil; all copper terminals.

- ♥【Highly Adaptable】High quality, high adaptability, high environmental adaptability, reliable operation even in extreme environments.

- ♥【Easy Installation】The base has fixing screw holes for a good fixing. Wiring can be used with spade type terminals for easy connection.

- ♥【Wide Range of Applicable 】Widely used in HVAC, lighting, elevators, compressors, printing presses, food processing, cranes, etc.Provide effective solution for circuit on/off.

- Carrier HVAC Contactor: 24VAC, 50/60Hz, amperage (FLA): 25A, resistive (RES): 15A, compatible devices up to 600 VAC

- UL Certified Replacement Relays: stable and durable, compact design to protect the contactor from dust and other environmental elements

- Industrial Workmanship: equipped with binding head screws, includes lug, covers and quick connect spade terminals, coils features class b insulation, coil is encapsulated with no exposed tape wrapping

- Wide Application: great switch solution for HVAC, elevators, pools, food processing, pumps or compressors, lighting, hoists and cranes, battery chargers, printing presses, vending machines, and agriculture

- Why You Choose Us: home and industrial facility should be available to everyone, you’ll get 1 x 1 pole motor contactor; If you can’t find the model you are looking for, contact us for assistance with your request

- Carrier HVAC Contactor: 2 pole 40 amp 24V coil air conditioner contactor, compatible devices up to 600 VAC; Our air conditioning motor contactors are essential components for efficient and reliable air conditioning system operation; The contactor is crafted with precision engineering and ideal quality materials to ensure optimal performance and reliability

- UL Certified Replacement Relays: with UL certification, our AC motor contactors are designed with precision and durability in mind to meet the demands of continuous operation and withstand harsh environments; From heavy machinery to HVAC systems, this contactor is the cornerstone of efficient motor control, providing reliable switching and protection for your equipment; Whether you are cooling a small room or a large commercial space, it can be a good help

- Industrial Workmanship: our HVAC motor contactors have a robust construction and ideal quality components with flame retardant shield, ideal quality silver alloy contacts that resist oxidation, full turn copper coils and all copper terminals for excellent longevity and reliability; With its robust design and exquisite electrical insulation, it provides reliable operation even in harsh conditions, ensuring uninterrupted operation when you need it most

- Installation is A Breeze: installation is quick and hassle free, and whether you’re an experienced HVAC technician or a DIY enthusiast, you’ll appreciate the easy to use setup that lets you get your air conditioner up and running in no time

- Wide application: our motor contactors are compatible with a wide range of air conditioning equipment, and can also be applied in HVAC, lighting, elevators, compressors, printing presses, food processing, cranes and other applications that require control circuits to be on/ off; It provides an effective solution for switching circuits

- PARAMETER: This AC contactor is 2 Pole, FLA 40 Amp rating, 24V coil, Normally Open (N.O.) Contact. The contactor meets specifications for devices up to 600 VAC

- HIGH-QUALITY MATERIALS: Heavy lug terminals and push-ons for high voltage connections. Silver alloy contacts for better conductivity. High-precision silicon steel core, pure copper coil and flame-retardant shell, this ac contactor is durable to serve several years. UL listed: E499854

- SAFE TO USE: Enclosed contacts and encapsulated 24 volt coil, which keep dust and dirt away, avoid arcing and sparks. You can use it safely and securely

- WIDE APPLICATION: Our definite purpose contactor can be used to replace most 2-pole contactors (rated current less than 40Amp) in 99 percent of household appliances and systems, such as HVAC, motors, heating and refrigeration systems. It can also replace Carrier, Bryant, Payne, Goodman, Amana, Janitrol, Rheem, Ruud, Weatherking, Lennox, Trane, American Standard and other brands. Good companions for your home life

- EASY INSTALLATION: It is very easy to install, just take a few minutes to replace one

- CERTIFIED: UL Recognized for application under UL File No. E527126 for USA and Canada; also rated for A2L refrigerants and approved for UL 60335, which is the future of HVACR electrical safety compliance.

- MEETS OEM STANDARDS: Our HVAC contactors are rigorously tested to meet OEM standards, exceeding those required by UL, including life cycle testing, environmental performance, and design specifications.

- INSTALLATION: Designed with an industry-standard mounting plate and can be used as drop-in replacements for existing HVAC and AC contactor installations. Typically used for specific applications and installed in end-use products and systems such as air conditioning, resistive heating, refrigeration equipment, hot tubs, and more.

- SPECIFICATIONS: 2 Pole / 40A / 24V AC Coil, Terminals: Line & Load Lugs, SCCR of 100kA at 600VAC, A/C Contactor. Westinghouse Model No. DW402A-110.

- WHAT’S INCLUDED: (1) Double-pole definite purpose contactor.

- CERTIFIED: UL Recognized for application under UL File No. E527126 for USA and Canada; also rated for A2L refrigerants and approved for UL 60335, which is the future of HVACR electrical safety compliance.

- MEETS OEM STANDARDS: Our HVAC contactors are rigorously tested to meet OEM standards, exceeding those required by UL, including life cycle testing, environmental performance, and design specifications.

- INSTALLATION: Designed with an industry-standard mounting plate and can be used as drop-in replacements for existing HVAC and AC contactor installations. Typically used for specific applications and installed in end-use products and systems such as air conditioning, resistive heating, refrigeration equipment, hot tubs, and more.

- SPECIFICATIONS: 1 Pole / 40A / 24V AC Coil, Terminals: Line Lugs & Load Screws, SCCR of 100kA at 600VAC, A/C Contactor. Westinghouse Model No. DW401A-120.

- WHAT’S INCLUDED: (1) Single-pole definite purpose contactor.

- Compatible Brands: The contactor is compatible with several well-known HVAC equipment brands, including, General Electric, Westinghouse, A.O. Smith, Janitrol, American Standard, Trane, Rheem, Ruud, Carrier, Bryant, Payne, Day & Night, Amana, Goodman, and more.

- Direct Replacement: It is designed as a direct replacement for many brands, simplifying the installation process and ensuring compatibility with a wide range of HVAC systems.

- High Quality & Strict Standards: All products are produced under strict quality inspection, CE and RoHS certified.

- Application: This contactor is widely used in air conditioning, heat pump, refrigeration systems, water pump and other household electrical appliances.

- Meets or Exceeds OEM Specifications: It is built to meet or even exceed original equipment manufacturer (OEM) specifications, indicating its compatibility with various HVAC systems.

- Production Name: AC Contacto

- Poles: 3 P

- Rated Current: FLA 40 Amp

- Coil Voltage:240 VAC

- Max.Withstand Voltage: 600 VAC

- Production Name: AC Contacto

- Poles: 1 P

- Rated Current: FLA 40 Amp

- Coil Voltage:24 VAC

- Max.Withstand Voltage: 600 VAC

- 👨🔧【Hvac Contactor】 AC contactor : 40 Amp 2 pole contactor 24 volt coil, 50/60Hz, compatible devices up to 600 VAC.

- 👨🔧【UL Certified Replacement Relays】Silver alloy contacts for better conductivity. High-precision silicon steel core, pure copper coil and flame-retardant shell,stable and durable, compact design which keeps dust and dirt away, avoids arcing and sparks. You can use it safely and securely.

- 👨🔧【Industrial Workmanship】Equipped with binding head screws, includes lug, covers and quick connect spade terminals, coils features class b insulation, Enclosed contacts and encapsulated 24 volt coil is encapsulated with no exposed tape wrapping.

- 👨🔧【Wide Application】Great switch solution for HVAC, heating, refrigeration systems, motors, elevators, pumps or compressors parts, lighting, pools, food processing, hoists and cranes, battery chargers, printing presses, vending machines, and agriculture. It is very easy to install, just take a few minutes to replace one, good companions for your home life.

- 👨🔧【Why Choose Us】High quality home and industrial facility should be available to everyone. If can’t find the model what you are looking for, please contact us for assistance with your request. 24*7 hours customer service.

Frequently Asked Questions (FAQ)

What are the signs that an AC contactor is going bad?

Can I replace an AC contactor myself?

How much does it cost to replace an AC contactor?

How long does an AC contactor last?

Can a bad AC contactor cause other issues?

Final Words: Maintaining and replacing your AC contactor for optimal performance

In conclusion, a well-functioning AC contactor is essential for the proper operation and efficiency of an air conditioning system. It acts as a switch, controlling the flow of electricity to the compressor and condenser fan motor.

Understanding the signs of a bad AC contactor is crucial for homeowners to be able to troubleshoot and diagnose issues. Some common signs include frequent circuit breaker trips, inconsistent cooling or heating, unusual noises, burn marks or damage on the contactor, difficulty starting or stopping the AC unit, and frequent electrical issues in the home.

There are several potential causes of AC contactor failure, including normal wear and tear, electrical overload, dust and debris accumulation, corrosion or rust, poor installation or maintenance, and power surges or voltage fluctuations. These factors can lead to reduced energy efficiency, increased energy consumption, potential damage to other components, and safety hazards and fire risks. To prevent AC contactor issues, regular preventive maintenance is crucial.

This includes regular cleaning and inspection, keeping the contactor area clear of debris, proper lubrication of moving parts, addressing electrical issues promptly, and scheduling professional maintenance. In the event of a bad AC contactor, it is important to replace it promptly. Before doing so, ensure proper safety precautions are taken, gather the necessary tools and equipment, shut off the power supply, remove the old contactor, install and wire the new contactor, and test and verify its proper functionality.