How Much Uv Dye To Use In Ac: The Ultimate Guide For Optimal Performance

When using UV dye in an AC system, the recommended amount to use is typically 1/4 ounce per pound of refrigerant. It is important to follow the manufacturer’s instructions and not exceed the recommended dosage. The UV dye helps to identify leaks in the system by glowing under UV light, making it easier to locate and fix any problems.

Are you an automotive technician or a DIY enthusiast with a passion for air conditioning repair and maintenance? If so, you know the importance of properly diagnosing and fixing AC system issues. One challenge you might face is determining the right amount of UV dye to add to the system for effective leak detection without causing any adverse effects on the AC components.

That’s where we come in. In this blog article, we will explore the question that has puzzled many: “How much UV dye should I use in my AC?” We understand that as an advanced AC professional or experienced DIYer, you’re looking for precise and practical information to guide you in your repairs.

That’s why we’ve compiled all the essential knowledge and tips to help you make informed decisions and achieve optimal results. Throughout this article, we’ll delve into the factors that influence the amount of UV dye to use, such as the size of the AC system and the severity of the leak. We’ll also discuss the potential consequences of using too much or too little dye and how to strike the right balance.

Additionally, we’ll address common misconceptions and provide step-by-step instructions for adding UV dye to your AC system. Whether you’re troubleshooting a stubborn leak or performing routine maintenance, having the right amount of UV dye in your AC system can make all the difference. Join us as we uncover the secrets of UV dye usage and empower you to become an even more knowledgeable and efficient air conditioning expert.

Factors Influencing UV Dye Usage

1. Size of the AC System

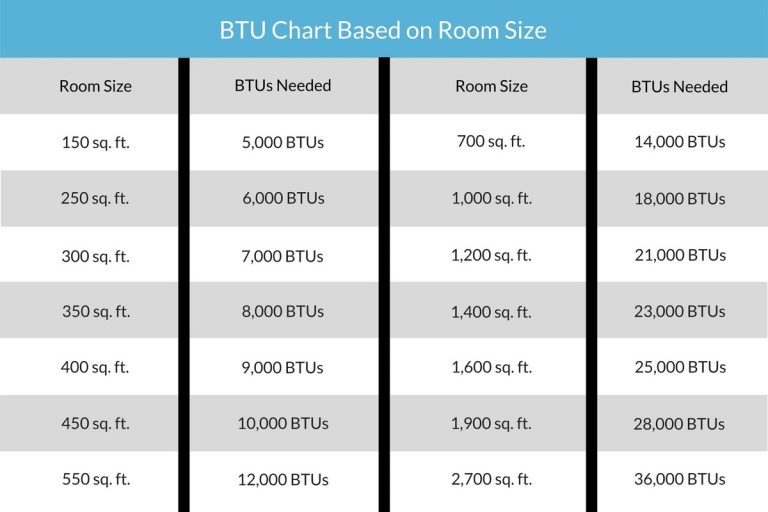

When determining the amount of UV dye to use in your AC system, it’s crucial to consider the size of the system. Larger systems require more dye to effectively detect leaks, while smaller systems require less. The size of the system is typically measured in tons, with residential units ranging from 1 to 5 tons and commercial units going up to 20 tons or more.

For residential systems, a general rule of thumb is to use approximately 1/4 ounce of UV dye per ton of cooling capacity. So, if you have a 3-ton AC system, you would need approximately 3/4 ounce of UV dye. However, it’s important to consult the manufacturer’s guidelines or the specific UV dye product instructions for accurate dosage recommendations.

2. Severity of the Leak

The severity of the AC system leak also plays a significant role in determining the amount of UV dye to use. If you’re dealing with a small leak, a minimal amount of dye may be sufficient to detect it. However, larger leaks may require a higher dosage of UV dye to ensure visibility under UV light.

To determine the severity of the leak, you can assess the rate at which the refrigerant is leaking from the system. If the leak is slow and gradual, a smaller amount of UV dye may be appropriate. However, if the leak is more significant and causing a noticeable decrease in refrigerant levels, a larger amount of dye will be necessary.

3. Manufacturer Recommendations

It’s always important to refer to the manufacturer’s recommendations when adding UV dye to your AC system. Manufacturers often provide specific instructions regarding the amount of dye to use based on the type and model of the system. These recommendations take into account the system’s design, components, and optimal performance.

Following the manufacturer’s guidelines ensures that you’re using the correct dosage of UV dye for your specific AC system, minimizing the risk of adverse effects and maximizing the effectiveness of leak detection.

The Consequences of Using Too Much UV Dye

While it’s essential to use the appropriate amount of UV dye for effective leak detection, using too much dye can have negative consequences on your AC system. It’s important to strike the right balance to avoid potential issues.

1. Adverse Effects on Components

Excessive amounts of UV dye can potentially contaminate the AC system and its components. The dye may accumulate in the refrigerant lines, condenser, evaporator coil, or compressor, hindering the system’s performance and potentially causing damage.

The dye can also cause blockages in the refrigerant flow, leading to reduced cooling capacity, increased energy consumption, and system malfunctions. This can result in decreased comfort levels, higher utility bills, and the need for costly repairs.

2. False Leak Indications

Using an excessive amount of UV dye can lead to false leak indications. When UV dye is present in large quantities in the system, it may fluoresce under UV light, even if there are no actual leaks. This can cause confusion and misdiagnosis, wasting time and effort in searching for non-existent leaks.

False leak indications can be particularly problematic in systems that have had UV dye added previously, as residual dye may still be present. It’s important to thoroughly flush the system and remove any remaining dye before adding a new dosage.

The Consequences of Using Too Little UV Dye

While using too much UV dye can cause issues, using too little can also lead to suboptimal leak detection results. Insufficient dye may not provide enough visibility under UV light, making it challenging to locate and identify leaks accurately.

1. Incomplete Leak Detection

If the amount of UV dye used is insufficient, it may not circulate adequately throughout the AC system. This can result in incomplete coverage and make it difficult to pinpoint the exact location of the leak.

Without sufficient dye, small leaks may go undetected or be mistaken for larger leaks due to the lack of fluorescence. This can lead to inaccurate diagnosis and potentially unnecessary repairs or component replacements.

2. Wasted Time and Resources

Using too little UV dye may require additional troubleshooting steps and repeated attempts to locate the leak. This can result in wasted time, effort, and resources, prolonging the repair process and causing frustration.

To avoid these issues, it’s essential to follow the recommended dosage of UV dye based on the size of the AC system, severity of the leak, and manufacturer’s guidelines.

Step-by-Step Guide to Adding UV Dye to Your AC System

Now that you understand the factors influencing UV dye usage and the potential consequences of using too much or too little dye, let’s walk through the step-by-step process of adding UV dye to your AC system.

Before you begin, gather the necessary materials:

- UV dye compatible with your AC system

- UV light or flashlight

- Protective gloves and goggles

Now follow these steps:

- Ensure that the AC system is turned off and the power supply is disconnected.

- Locate the service valve on the low-pressure side of the AC system. This is usually found on the suction line near the evaporator coil or compressor.

- If necessary, remove the service valve cap and attach the UV dye injection hose to the valve.

- Refer to the UV dye product instructions for the recommended dosage. Measure the appropriate amount of UV dye using a syringe or measuring cup.

- Insert the UV dye into the AC system by gently squeezing the dye injection hose or following the specific instructions provided with the UV dye product.

- Ensure that the UV dye is evenly distributed throughout the system by running the AC system for a few minutes.

- Inspect the entire AC system, including refrigerant lines, connections, coils, and fittings, under UV light or using a UV flashlight. Look for any signs of fluorescence indicating leaks.

- If leaks are detected, mark their locations for future repair. Take precautions to avoid direct contact with the UV dye, as it may stain clothing and surfaces.

- If no leaks are found, the system can be recharged with refrigerant and returned to normal operation.

Following these steps will help ensure that you add the right amount of UV dye to your AC system for effective leak detection without causing adverse effects.

Common Misconceptions about UV Dye Usage

Before we wrap up, let’s address some common misconceptions about UV dye usage in AC systems:

1. More Dye Means Better Leak Detection

While it may seem logical to assume that using a larger amount of UV dye will result in better leak detection, this is not necessarily true. The optimal amount of UV dye is determined by the factors we discussed earlier, such as the size of the system and the severity of the leak. Using excessive amounts of dye can lead to the issues we mentioned earlier, such as component damage and false leak indications.

2. UV Dye Eliminates the Need for Other Diagnostic Methods

UV dye is a valuable tool for leak detection in AC systems, but it should not be relied upon as the sole diagnostic method. It’s important to use UV dye in conjunction with other methods, such as pressure testing, visual inspection, and electronic leak detection, to ensure comprehensive and accurate results. Each method has its own strengths and limitations, and combining them increases the chances of successful leak detection.

3. UV Dye Does Not Affect AC Performance

While UV dye is generally safe for AC systems when used in the correct dosage, it can have an impact on performance if used excessively. As we discussed earlier, excessive dye can cause blockages, reduce cooling capacity, and lead to system malfunctions. It’s important to follow the recommended dosage and flush the system properly if residual dye is present.

By understanding these misconceptions, you can make more informed decisions when adding UV dye to your AC system, ensuring optimal results and avoiding unnecessary problems.

In Conclusion

Adding UV dye to your AC system can be a valuable tool for leak detection, but it’s crucial to use the right amount to avoid adverse effects. Factors such as the size of the system, severity of the leak, and manufacturer’s recommendations should be considered when determining the dosage.

Using too much UV dye can lead to component damage, false leak indications, and performance issues, while using too little can result in incomplete leak detection and wasted time. By following the recommended dosage and incorporating other diagnostic methods, you can achieve accurate and comprehensive results.

Next time you encounter an AC system with a suspected leak, confidently add the appropriate amount of UV dye, and let it guide you to the source of the problem. With the right dosage and thorough inspection under UV light, you’ll be well-equipped to tackle any AC leak and restore optimal performance.

How to Find AC Leaks in Your Car (UV Dye)

Frequently Asked Questions (FAQ)

How much UV dye should I use in my AC?

Can I use too much UV dye in my AC?

How do I know if I have added enough UV dye to my AC system?

How often should I add UV dye to my AC system?

Can UV dye harm my AC system?

Conclusion: The Importance of Proper UV Dye Usage for Effective AC Leak Detection

In conclusion, determining the appropriate amount of UV dye to use in your AC system is essential for effective leak detection. Factors such as the size of the system, severity of the leak, and manufacturer’s recommendations should be carefully considered.

It is generally recommended to use approximately 1/4 ounce of UV dye per ton of cooling capacity for residential systems. However, it’s crucial to consult the manufacturer’s guidelines or specific product instructions for accurate dosage recommendations.

Using too much UV dye can have adverse effects on the AC system, including component damage, blockages, and false leak indications. On the other hand, using too little UV dye may result in incomplete leak detection and wasted time. It’s important to strike the right balance to avoid both issues.

Following a step-by-step guide when adding UV dye to your AC system can help ensure accurate results. It involves measuring and injecting the appropriate amount of UV dye, distributing it evenly throughout the system, and inspecting the system under UV light for fluorescence indicating leaks. It is important to note that there are some common misconceptions about UV dye usage.